Lonten Tech

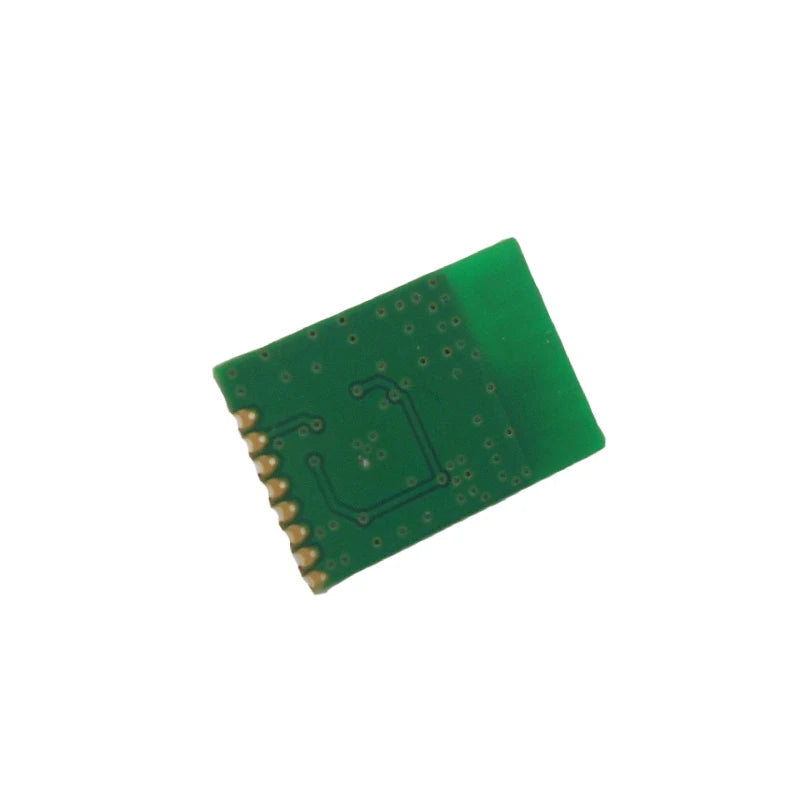

Custom CC2500 wireless module 2.4g small size and high cost-effectiveness CC2500RTKR chip

Custom CC2500 wireless module 2.4g small size and high cost-effectiveness CC2500RTKR chip

Couldn't load pickup availability

Using TI's CC2500 original chip and independently developed RF wireless module, the performance is stable and reliable. This product has a mature production line. The stamp interface is gold-plated, and the output power and reception sensitivity are better than the binding module! Adopting TXC wide temperature and high-precision crystal oscillator, Japanese Murata high-precision inductor and capacitor, suitable for industrial occasions! Fully compatible with older versions of bare chip modules!

Customers with high product quality requirements should use modules made from TI original CC2500 chips for the following reasons:

1. The binding module is bound with resin, and its thickness and shape are difficult to ensure consistency, which affects the consistency of high-frequency parameters; To save costs, pins are bound with cheap aluminum wires, which have relatively poor conductivity and reliability. However, TI original chips have undergone strict testing before leaving the factory. Especially in situations where batteries are used for power supply, resin is prone to introducing impurities during processing, which can lead to some modules being slightly leaky and causing premature battery consumption. For situations with severe vibration and temperature changes, modules made with original ICs should also be considered.

2. Binding modules are generally used in low-end product scenarios, with low prices. In order to save costs, some filtering capacitors are usually omitted, and inductors are simulated using PCB wires. However, the accuracy of PCB wire width is generally within 20% in factories. Therefore, the consistency and stability of the modules produced are worse than those produced by regular packaging chips. Special attention should be paid to users who require CC2500 RSSI signal strength indication. Some even skip the entire province of bandpass filtering circuits and only perform impedance matching. Although the transmission may seem fine, the loss of low noise filtering circuits greatly reduces the signal-to-noise ratio of reception, and in severe cases, the reception is unstable!

3. After the binding module is damaged, it cannot be repaired and can only be scrapped. However, modules made from TI's original IC can have their chips removed and replaced with new ones

4. The binding module is bound with aluminum wire, establishing a connection between the copper sheet of the wafer and PCB. The melting point of aluminum wire is over 600 degrees, while the melting point of copper is 1043 degrees. Due to the extremely high temperature, it will affect the high-frequency parameters of the circuit board, thereby greatly reducing the consistency and lifespan of the product.

The prices of CC2500 modules made from TI original ICs on the market are relatively high, and bare chip modules cannot meet the requirements of customers with high quality requirements. In response to the demands of our customers, our company has specially developed this module and lowered the price a bit, so as not to increase the cost as much as possible for customers who originally used bound modules. At the same time, we also thank these old customers for coming all the way from the initial cylindrical crystal oscillator binding module to the SMT crystal oscillator module.

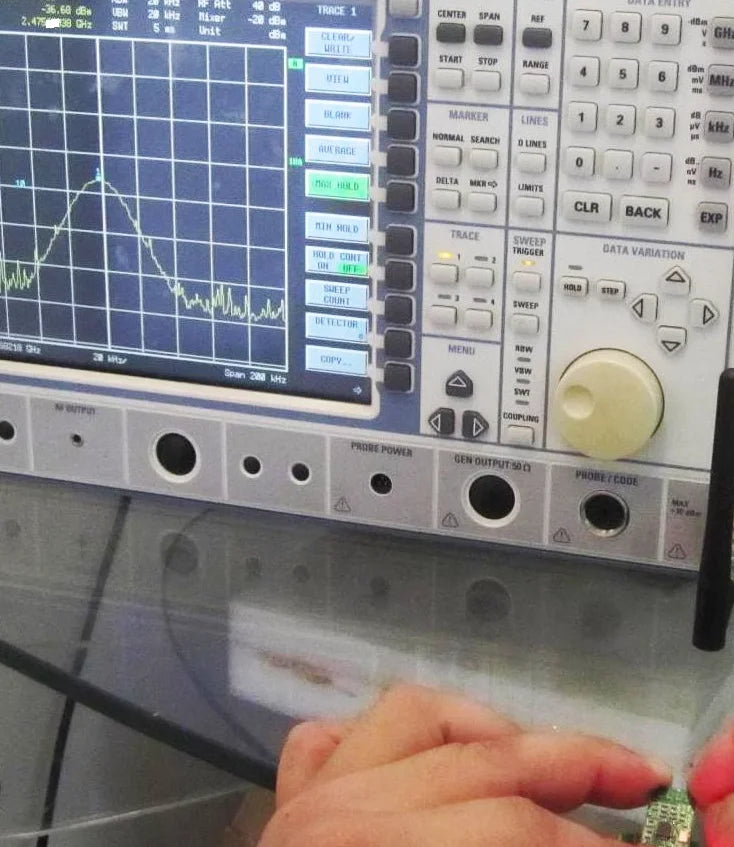

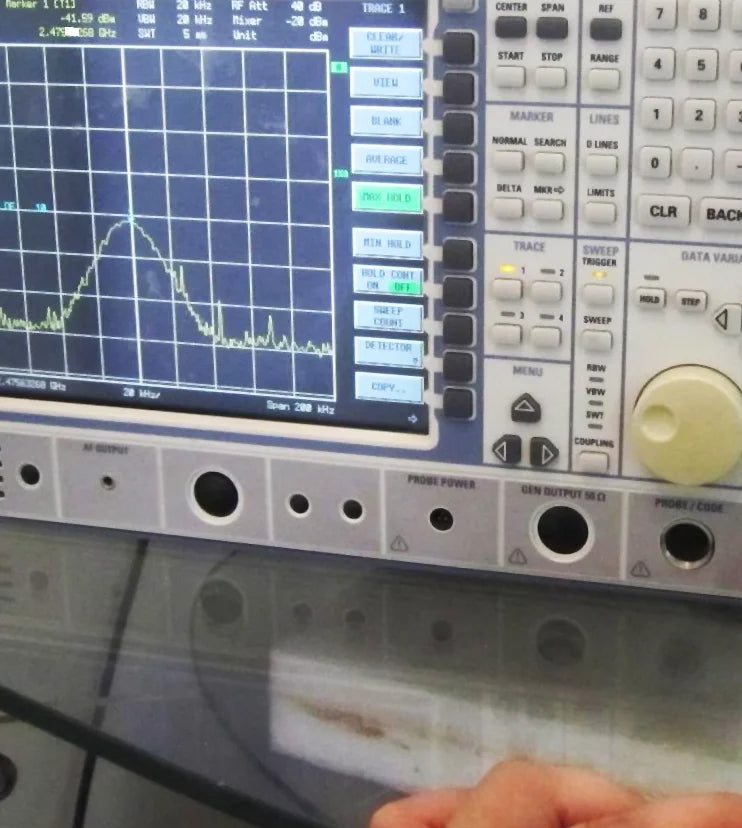

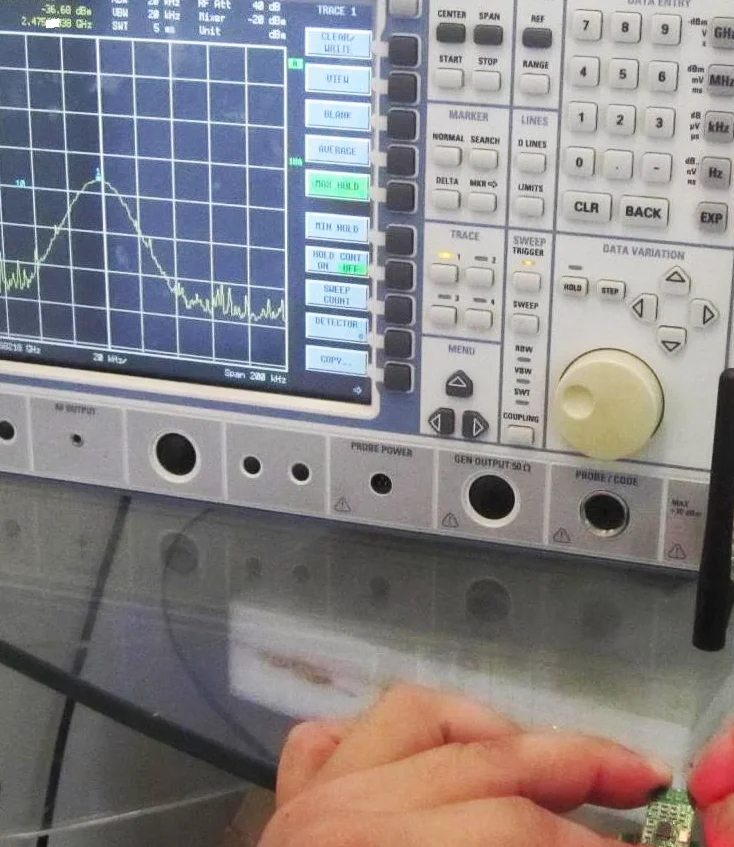

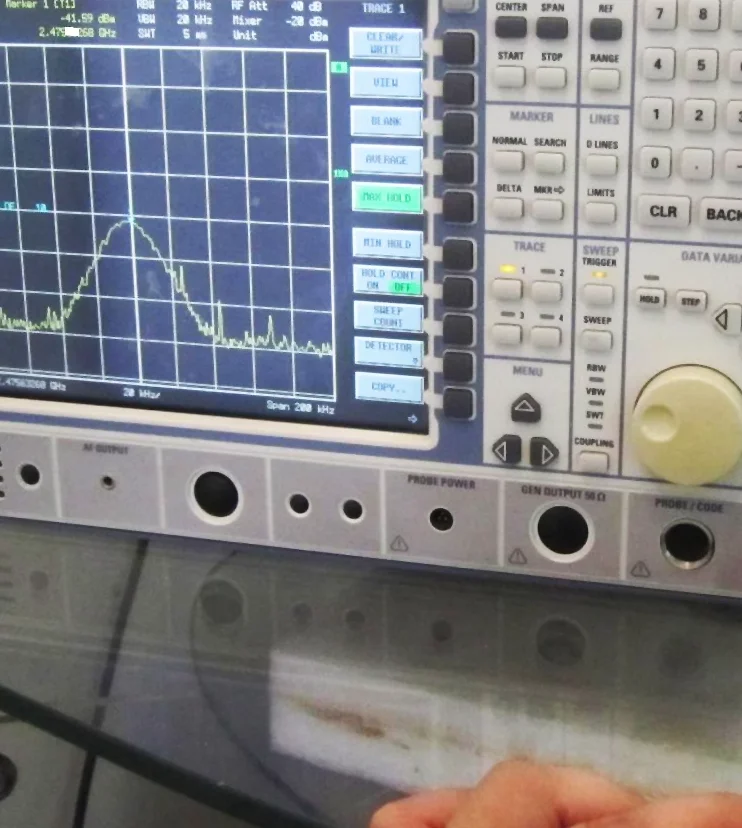

From the above figure, it can be seen that the new IC module has a higher transmission power of -36.68- (-41.59)=4.91dBm than the bound module, and the harmonics are also smaller.

The main performance is as follows:

1. Working frequency 2.4GHz, effective frequency: 2400-2483.5 MHz ISM/SRD band

2. The transmission distance in open spaces is greater than 50 meters. Equipped with PCB antenna, no need for additional antenna!

3. Low current loss, with a software adjustable emission current of 11mA to 21mA and a receiving current of 15mA. Equipped with wireless wake-up (WOR, 900nA) function, it can wake up your microcontroller wirelessly. The sleep current is less than 500nA, making it an ideal product for remote control and active RFID. For detailed power consumption, please refer to page 6 of the CC2500 IC manual.

4. SPI serial programming interface

5. Working temperature range: -40 ℃ to+85 ℃, within the range of -20 ℃ to 70 ℃, with an accuracy of+-10ppm.

6. Working voltage: 1.8-3.6 volts.

7. Effective frequency: 2400-2483.5 MHz ISM/SRD band

8. High sensitivity, programmable output power

9. The transmission rate can reach 500Kbps.

10. Supports programmable 255 channels, making it easy to implement frequency hopping functionality. Bandwidth can be divided by setting registers.

11. External dimensions 12 * 18 * 2 mm

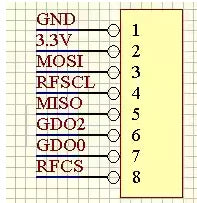

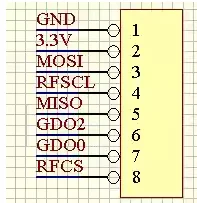

12. The circuit connections are as follows

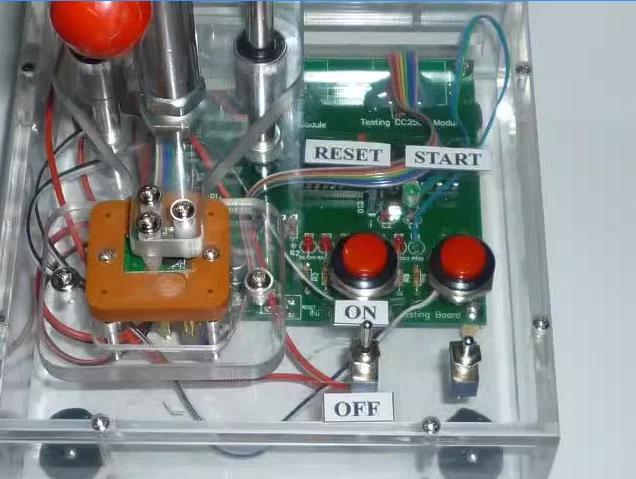

The following diagram is one of the testing tools, and all products of our company are fully inspected. The testing steps for this product can be found in the fourth picture of the product. The test bench in the figure has added a validated RF signal attenuation device, which can effectively test communication distance!

1、 Provide CC2500 chip information in both Chinese and English, as well as module information in English.

2、 Provide Protel99 schematics, module packaging, and over 800 lines of accumulated code written in standard C, making it easy to port to platforms such as 51, AVR, PIC, and ARM. The software development package program includes wireless sending, wireless receiving, and wireless receiving interrupt response programs. In an 8-bit microcontroller environment, it requires approximately 2.2KB of program memory space. Of course, if you are very familiar with your microcontroller system, you can further optimize it.

3、 Easy to use, the code includes directly simulating SPI ports with IO ports, which means that as long as there are 5 IO ports, module communication can be started. GDO2 is usually not connected, and those with high requirements can connect a small capacitor to ground.

Share