1

/

of

6

Lonten Tech

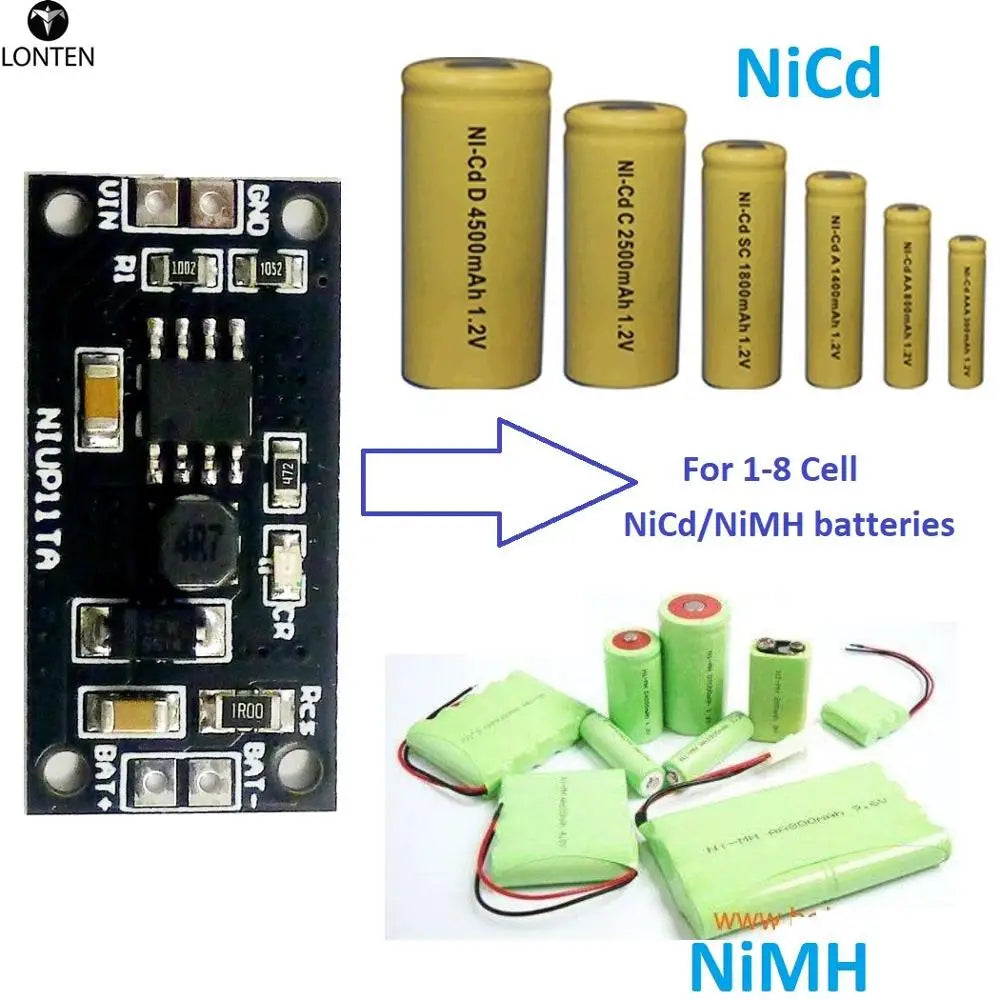

Custom 1-8 Cell 1.2V 2.4V 3.6V 4.8V 6V 7.2V 8.4V 9.6V NiMH NiCd Battery Dedicated Charger Charging Module Board Manufacturer

Custom 1-8 Cell 1.2V 2.4V 3.6V 4.8V 6V 7.2V 8.4V 9.6V NiMH NiCd Battery Dedicated Charger Charging Module Board Manufacturer

Regular price

$2.51 USD

Regular price

$2.51 USD

Sale price

$2.51 USD

Unit price

/

per

Couldn't load pickup availability

Lonten provide electronic component ,welcome OEM CUSTOM ,ODM,for more please contact.

Product Name: 1-8 Cell 1.2V 2.4V 3.6V 4.8V 6V 7.2V 8.4V 9.6V NiMH NiCd Battery Dedicated Charger Charging Module Board

Packing list:

1 PCS 1-8 cell NiCd/NiMH batteries Charger Module

(Please choose the parameters you need when purchasing)

(Please choose the parameters you need when purchasing)

Description:

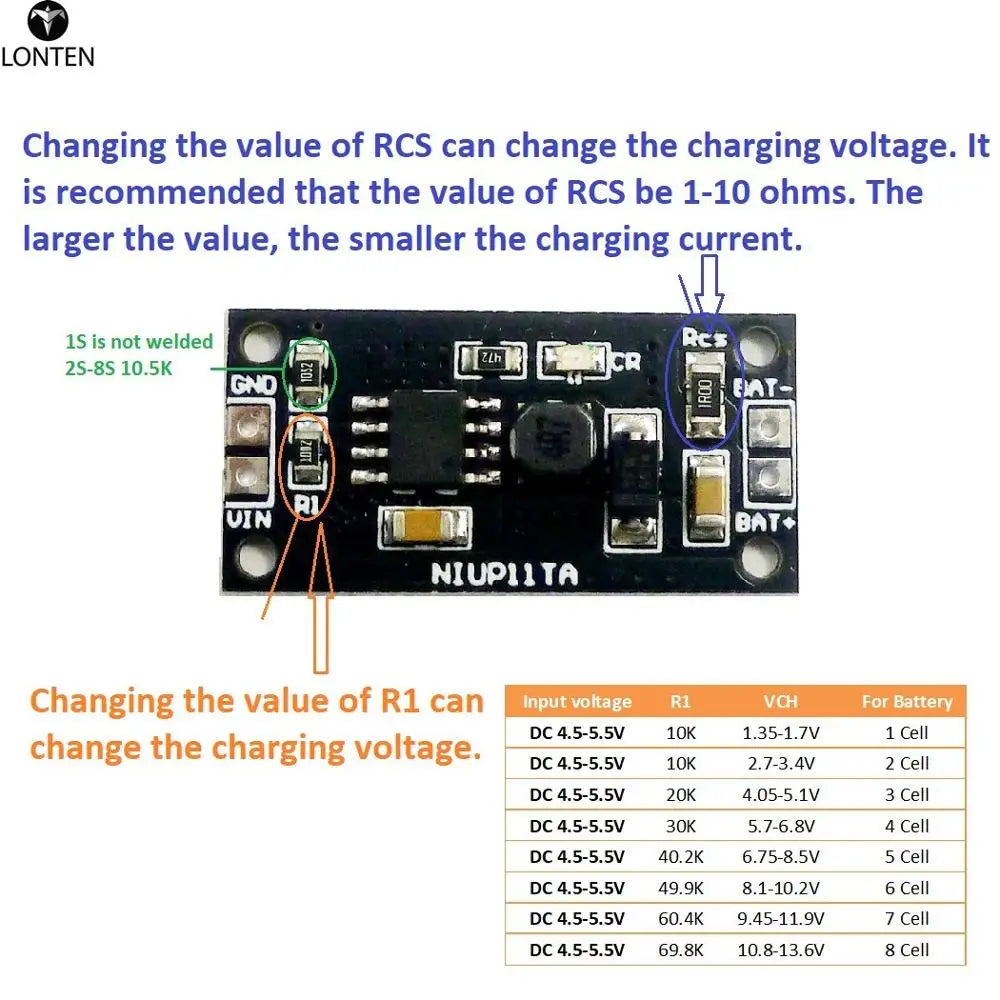

1-Cell(1S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 1.35V-1.7V

Charging current about : 230mA-240mA

2-Cell(2S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 2.7V-3.4V

Charging current about :230mA-240mA

3-Cell(3S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 4.05V-5.1V

Charging current about : 230mA-240mA

4-Cell(4S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 5.7V-6.8V

Charging current about : 230mA-240mA

5-Cell(5S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 6.75V-8.5V

Charging current about : 230mA-240mA

6-Cell(6S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 8.1V-10.2V

Charging current about : 230mA-240mA

7-Cell(7S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 9.45V-11.9V

Charging current about : 190mA-210mA

8-Cell(8S) Version:

Input voltage : DC 4.5V-5.5V(Recommend DC 5V)

Charging voltage about : 10.8V-13.6V

Charging current about : 190mA-210mA

USB power protection

Short circuit protection and zero volt battery activation

Battery protection

Operating ambient temperature : -40° to +85°

Storage temperature : -65° to +125°

Size 30mm x 15mm x 4mm

Weight : 1.5g

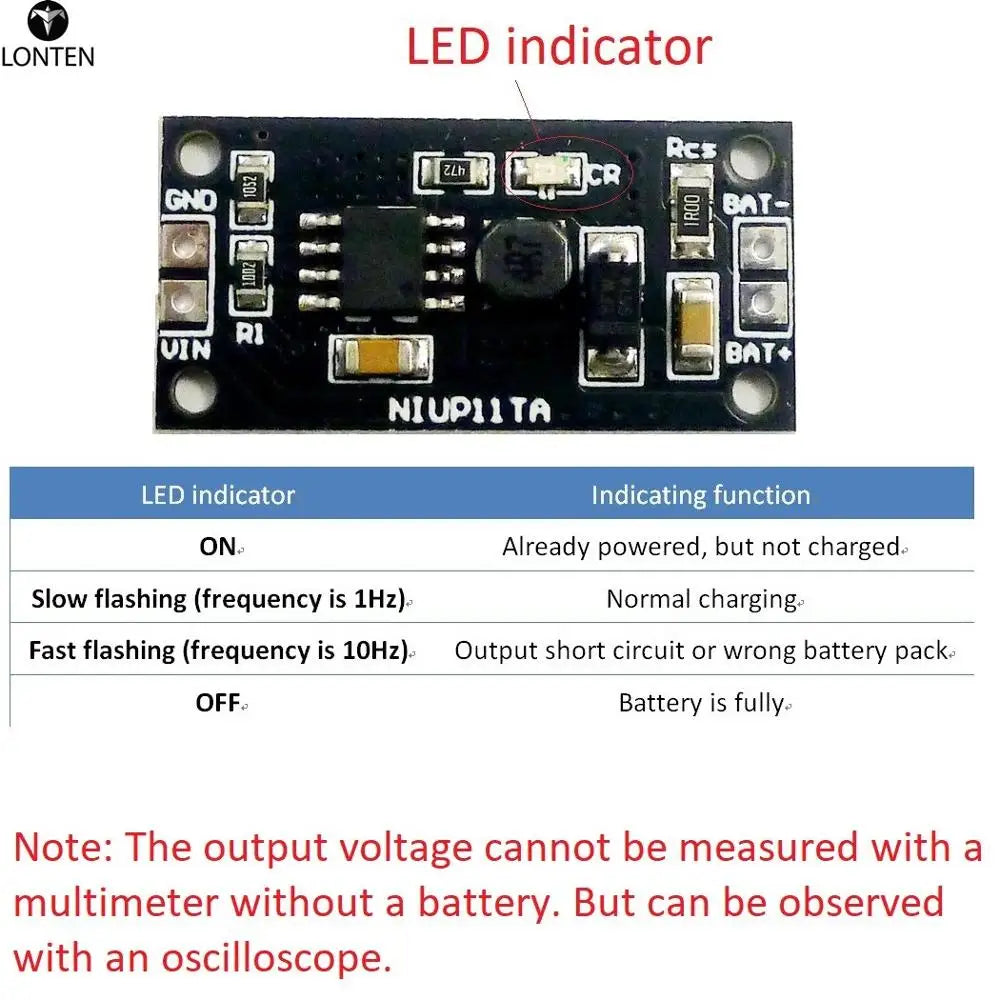

Note: The output voltage cannot be measured with a multimeter without a battery. But can be observed with an oscilloscope.

Tip: If your battery is 1-3Cell, please choose a high current version: NIMHCRTA

Applications:

kids toys car

Digital Cameras

Solar charging

Bluetooth Applications

o equipment

Digital Camera

Electronic Dictionary

Portable Devices

1-8Cell Nickel Metal Hydride Battery Charger

1-8Cell NiCd Battery Charger

USB power protection:

When charging multiple batteries, the USB power supply needs to supply a large current. In order to ensure that no USB power is damaged, the NIUP11TA as USB power protection. When the USB power supply voltage is pulled down to a certain threshold, reduce the charging current to protect the USB power supply. When the USB power supply voltage rises, adjust the charging current to the maximum value.

Short circuit protection and zero volt battery activation:

NIUP11TA can intelligently detect whether the output is short-circuited and indicate an error. The NIUP11TA allows long-term shorts in the output without damaging any circuitry and USB power, and the output is shorted and maintains low power consumption.

The NIUP11TA has a zero-volt battery activation function that determines a zero-volt battery when the short-circuit is detected for the first time after power-on. The horse activates the zero-volt battery, and the zero-volt battery activates and enters the normal charging process. If the zero volt battery is not activated, it will be judged to be a short circuit and the indicator light will start flashing.

Battery protection:

1) If the battery voltage is higher than 1.35V, the battery is considered to be close to full capacity. After plugging in, it will not be charged, and the indicator light will be extinguished to prevent the battery capacity from dropping due to the memory effect of the nickel-cadmium battery.

2) After the battery is connected, the number of battery packs will be judged. If the voltage is not within the corresponding range, charging will not be performed.

Charging process:

1) Battery insertion detection

When the charger is up, it will automatically detect the presence or absence of battery insertion. After detecting the zero-volt battery, it will be activated automatically. When the short-circuit is detected, an error will be indicated. If the number of battery packs is not matched with the circuit, an error will be reported. After the correct battery pack is inserted, normal charging will be performed.

2) Pre-charge

If the battery pack connected to the battery pack is less than 1V, it indicates that the battery is discharged too much. It needs to be activated after a small current is activated to prevent damage to the battery. Pre-charging requires a current of 100 mA and a fast charge when the single cell voltage is greater than 1V.

3) Fast charging

If the battery pack connected to the battery pack is already greater than 1V, it indicates that the battery has passed the precharge threshold and can be quickly charged. Fast charging requires current to be controlled at 250mA. The fast charging process should periodically detect the battery voltage and charging current, and detect the battery voltage -v or 0△V, and jump to make up the charging.

4) make up the charge

Fast charging has been used to charge the battery voltage to 1.3V or higher with a large current. If fast charging is used, the temperature of the battery will rise rapidly. It needs to be changed to a smaller current to make up the charge. At this time, the current is controlled at 200mA. Make up the charging time for 20 minutes, and then jump to trickle charging after the end of the charge.

5) trickle charging

In order to make up for the self-discharge of the battery, it will enter the trickle charge after the end of charging. The trickle charge current is 40mA. After entering the trickle charge, the indicator light has been extinguished. When the user removes the battery, it will enter the next charge cycle.

6) Battery take-out detection

When charging is entered, the system will continue to take the battery removal test. After detecting that the battery is removed, it will enter the next charging cycle.

Share